Stabilizing Warped Globe Paper: Methods for Flattening and Preservation

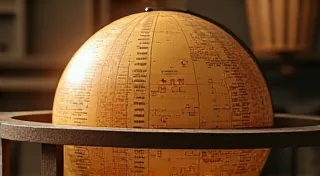

One of the most common challenges encountered when repairing antique globes is dealing with warped paper. Decades of storage, changes in humidity, and even the globe's inherent construction can all contribute to the paper maps curving and distorting. Attempting to flatten warped paper incorrectly can cause tears, cracking, or irreversible damage. This guide explores safe and effective methods to address this issue, preserving the beauty and value of your vintage globe.

Understanding the Causes of Warping

Before attempting any repairs, it's crucial to understand why the paper has warped. Common causes include:

- Humidity Fluctuations: Paper is hygroscopic, meaning it absorbs moisture from the air. Repeated cycles of wetting and drying cause expansion and contraction, leading to warping.

- Improper Storage: Storing a globe rolled or stacked can create pressure points and cause permanent deformation. This is particularly problematic for older globes where the paper isn’t as robust.

- Globe Construction: The inherent curvature of the globe and the glue used in its construction can contribute to paper warping over time. The adhesives used historically are often more susceptible to degradation and can exacerbate warping issues.

- Paper Type: The type of paper used in the globe's construction also plays a role. Older, more delicate papers are more susceptible to warping. The fragility of these antique papers often requires a more nuanced and cautious restoration approach.

Gentle Assessment – Before You Begin

Carefully examine the warped section. Note the severity of the warp and any existing cracks or tears. Attempting to force a severely warped section flat could exacerbate existing damage. A gentle, gradual approach is key. Sometimes, the damage is so extensive that a full re-attachment of the paper to the globe is required, a process best left to professionals. Learn more about repairing loose globe paper when the issue is beyond simple flattening.

Method 1: The Humidification & Weighting Technique

This is generally the safest and most recommended method. It involves carefully increasing the paper’s moisture content and then using weight to gently coax it back to a flatter state.

- Humidity Control: A controlled humidification environment is crucial. A humidity chamber (a sealed container with a shallow dish of water) or even a bathroom with a running shower (allowing steam to fill the room) can be used. Avoid direct water contact with the paper.

- Monitoring: Monitor the paper's condition frequently during humidification. You're aiming for a damp, pliable state, not saturation. This process can take several hours, so patience is essential.

- Weighting: Once the paper is sufficiently dampened, place it between two sheets of acid-free paper and gently weigh it down with smooth, flat objects like books or glass weights. Ensure the weights are evenly distributed to prevent further distortion.

- Drying: Allow the paper to dry completely under the weight, away from direct sunlight or heat. This may take several days. Careful observation of the drying process is crucial to avoid unexpected changes in the paper’s condition.

Method 2: The Controlled Heat Press (Advanced – Use with Caution)

A low-temperature heat press, carefully controlled, may be used to flatten more severely warped sections. The paper is placed between layers of acid-free paper and pressed at a temperature of around 150°F (65°C) for a very short duration (a few seconds). Immediate cooling and careful monitoring are essential. The condition of the globe’s supporting structure is also important; a deteriorating globe stand can contribute to overall instability and paper stress. Understanding the original construction and materials is paramount for successful restoration.

Preventative Measures & Long-Term Preservation

Once the paper is stabilized, proactive steps can prevent future warping:

- Stable Environment: Store the globe in a location with consistent temperature and humidity. A dedicated storage area, away from direct sunlight and fluctuating temperatures, is ideal.

- Acid-Free Storage: Use acid-free materials for storage and any repairs. This helps to prevent the paper from becoming brittle and discolored over time.

- Avoid Direct Sunlight: Sunlight can fade the paper and accelerate deterioration. UV-resistant glass or film can be used to protect the globe from harmful UV rays.

- Regular Inspection: Periodically inspect the globe for signs of warping or damage. Early detection of problems can prevent them from becoming more serious.

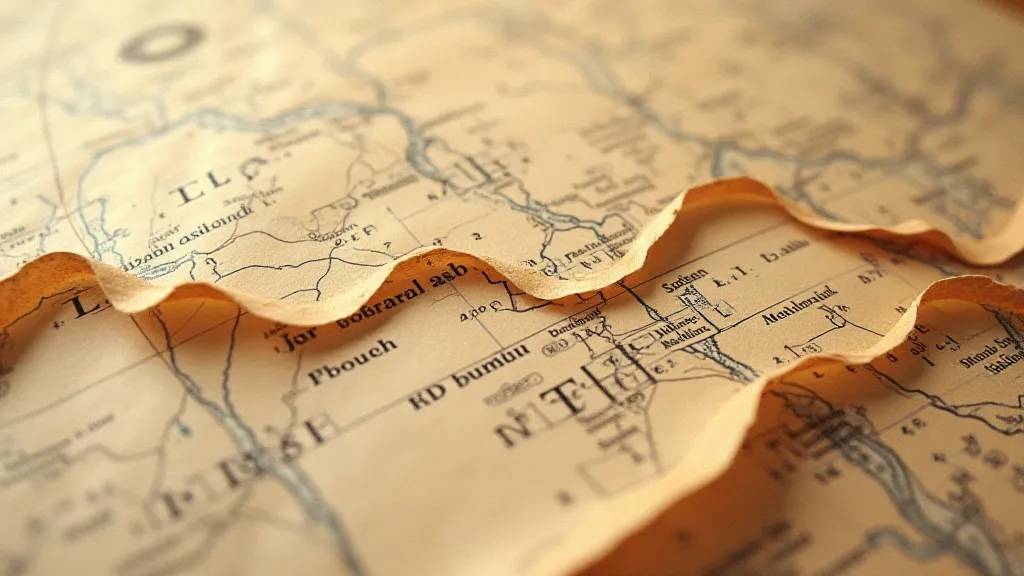

Special Considerations for Antique Maps

Remember that antique globe paper is often part of larger, hand-drawn maps. These maps often contain delicate features and intricate details. Approach any restoration with utmost care and prioritize preservation over perfect flatness. Minor imperfections are part of the globe's history and charm. Often, the artistic merit and historical significance are more valuable than achieving absolute perfection. Maintaining the original patina adds to the globe's authenticity and character.

Seeking Professional Help

If you're unsure about any aspect of the repair process, or if the warping is severe, it's best to consult a professional globe restorer. They have the expertise and specialized tools to handle delicate restorations. They can also advise on the historical context of the globe, including the meaning and interpretation of the cartouches often found on antique globes.

Additional Tips for Globe Paper Restoration

Beyond the specific techniques outlined above, several general principles apply to successful globe paper restoration. Firstly, a thorough understanding of the globe's original construction is vital. Researching the period when the globe was made can provide valuable insights into the types of paper and adhesives used. Secondly, always test any restoration technique on a small, inconspicuous area of the paper before applying it to the entire surface. This helps to identify any potential adverse effects. Finally, remember that restoration is an art as much as a science, and a degree of artistry and creativity may be required to achieve the best results.

Understanding Different Paper Types

The type of paper used in antique globes varies considerably depending on the era and manufacturer. Early globes often used handmade paper, which is characterized by its unique texture and slight imperfections. Later globes may have used machine-made paper, which is generally more uniform in thickness and quality. Identifying the type of paper can inform the restoration approach, as different papers may respond differently to various treatments. For example, handmade paper may be more susceptible to damage from moisture, while machine-made paper may be more prone to cracking.

Adhesive Considerations for Globe Repair

When reattaching loose paper or securing repairs, it's crucial to use an appropriate adhesive that won't damage the original paper. Traditional adhesives like wheat starch paste are often preferred because they are reversible and relatively gentle. However, it's important to prepare the adhesive correctly to ensure proper adhesion and prevent further deterioration. Modern conservation adhesives are also available, but it's important to choose a product that is compatible with the original materials.